The CEOs of TSMC, Taiwan’s globally critical chipmaker, and ASML, the Dutch company that provides the machines all cutting edge semiconductors are made with, have welcomed the release of a new software library called cuLitho that is designed to support the emerging challenges of nanoscale computational lithography.

Lithography, the process of creating patterns on a silicon wafer, requires massive computational workloads that consume tens of billions of CPU hours every year. cuLitho creator NVIDIA says that deploying it lets 500 NVIDIA DGX H100 systems (GPU-packed integrated hardware systems) achieve the work of 40,000 CPU systems.

Comments from the CEOs of the most influential chip players in the world suggest this is more than hyperbole.

““The cuLitho team has made admirable progress on speeding up computational lithography by moving expensive operations to GPU,” said Dr. C.C. Wei, CEO of TSMC. “This development opens up new possibilities for TSMC to deploy lithography solutions like inverse lithography technology and deep learning more broadly in chip manufacturing, making important contributions to the continuation of semiconductor scaling.”

See also: You can now use AWS to run GPU workloads — in containers, on-premises

Peter Wennink, CEO of ASML said: “Our collaboration with NVIDIA on GPUs and cuLitho should result in tremendous benefit to computational lithography, and therefore to semiconductor scaling.

"This will be especially true in the era of high NA extreme ultraviolet lithography,” he added on March 21: “We are planning to integrate support for GPUs into all of our computational lithography software products.”

Semiconductor developments increasingly require optical proximity correction (OPC) or inverse lithography technology (ILT) to accurately image wafers that require advanced computational lithography techniques all of which make huge computational demands. NVIDIA said: “Faster OPC enables new lithography innovations to address miniaturization of next-generation semiconductors, including subatomic modeling, curvilinear OPC, and high-numerical aperture extreme-ultraviolet (high-NA EUV) lithography” – all of which, away from the esoterica of such terms for those who don’t track this end of the market, ultimately mean faster and more energy efficient chips downstream for businesses and even consumers just as Moore’s Law seems dead.

cuLitho release: Lithograpy requires increasingly intensive compute

Electronic design automation firm Synopsys is also deploying cuLitho into their software, manufacturing processes and systems. The company explained the industry challenge around lithography as follows.

“As transistor sizes shrink, the lithographic process must become more precise to transfer the patterns from the photomasks on to the wafer with greater accuracy. At very small sizes, when features are closer together, it’s generally not feasible to obtain a clean and accurate representation of the mask’s patterning on the wafer.”

“ The diffusion of the light impacts resolution, causing blurring or distortion [which mean] important elements of the chip could be missed. Computational lithography has emerged to compensate for any image errors that could stem from diffraction or optical, resist, and etching proximity effects. Through OPC software, the process does so by playing tricks with the light via an algorithmic and mathematical approach, along with a lot of simulation work.

"The process involves going through different “what if?” scenarios to find the right configuration to print a pattern with the highest accuracy possible. For example, projecting light with the right artifacts around it, such as serifs that can manipulate the light, can generate a print on the wafer that is closer to the original than without these carefully selected artifacts,” wrote the company’s Anjaneya Thakar, a senior product manager.

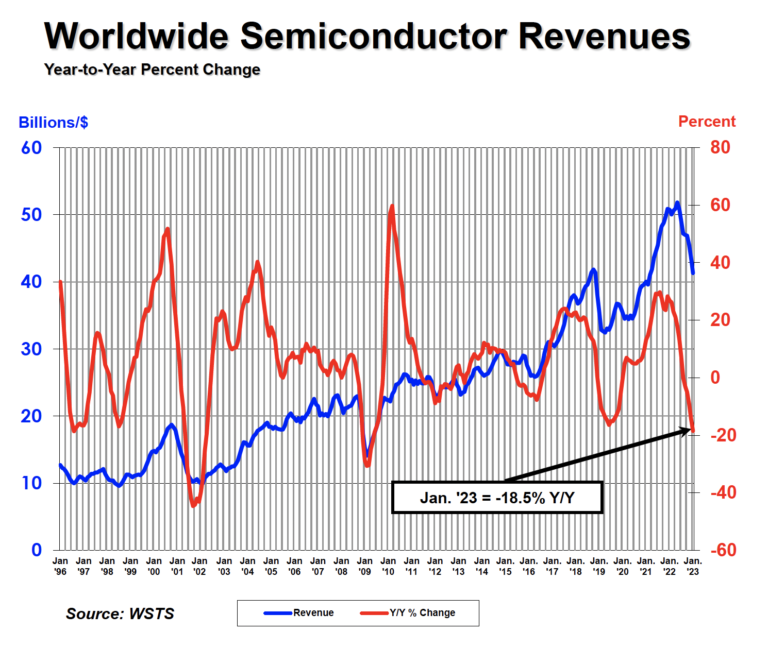

Chip sales reached their highest-ever annual total in 2022, hitting $573.5 billion. But semiconductor Industry Association data shows that sales were $41.3 billion in January 2023, a decrease of 5.2% compared to the December 2022 total of $43.6 billion and 18.5% less than the January 2022 total of $50.7 billion.